Dear all Netro customers,

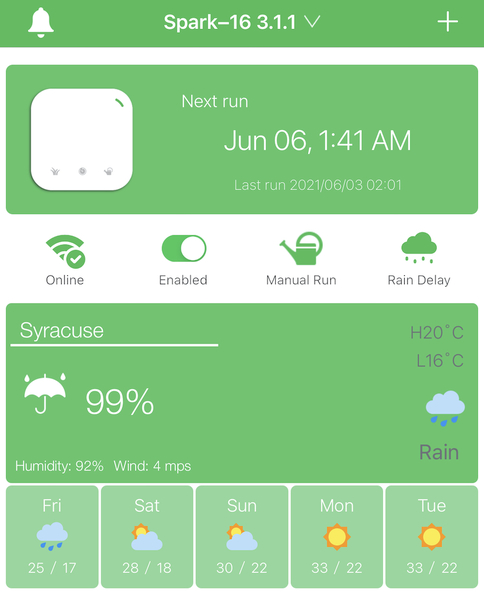

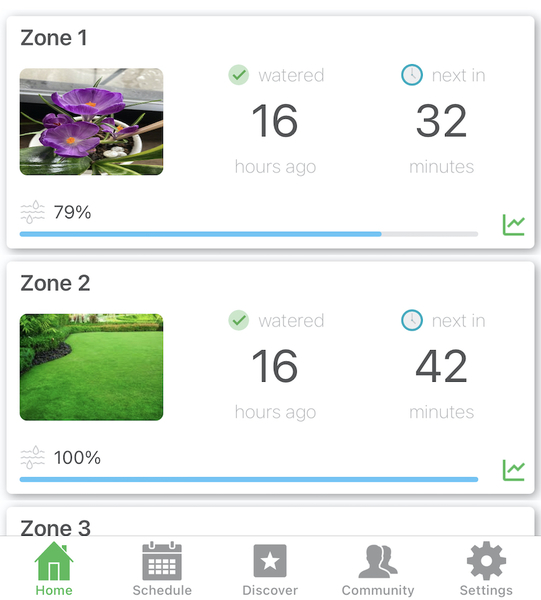

The long waited new version (3.0.0) of the Netro app is on the horizon. The major improvements of this version are

1. faster in loading data

2. new manual run interface

3. new home view design

4. more languages supported

We sincerely invite you to join the Beta testing program. Please email to support@netrohome.com or leave a message below if you would like to try the new app. Any feedback would be greatly appreciated !

Thanks,

Netro App Team